Reimagining enteral feeding tubes to feel less clinical

Redesigning a low-profile enteral feeding tube to feel less like a medical device and more like an accessory, focusing on user-centered design and safety.

Roles

User Research

Sketching

Prototyping

Tools

Illustrator, InDesign, Photoshop

SolidWorks

3D Printing in Resin

Mentor

Jeff Kapec

Intro

Enteral nutrition, also called tube feeding, is a method used to provide the daily intake of nutrients directly to the gastrointestinal (GI) tract. Temporary tubes, such as nasogastric tubes, are placed through the nose, pass by the esophagus, and deliver food to the stomach. A more permanent solution are Percutaneous Endoscopic Gastrostomy (PEG) tubes, which are placed through the abdominal wall.

How can patients with PEG buttons be relieved of their discomfort surrounding the issues around their tubes?

PEG tubes are used by patients that have digestive problems caused by a high-risk disease or birth defects. These tubes allows them to keep living. After a few months, some patients opt to use low-profile tubes, called buttons, that provide a more comfortable and concealed solution, but still have many issues.

Discover

Problem Definition

Standard feeding tubes and buttons have a balloon as a retaining mechanism, which can deflate or rupture.

Clogged Tube

Feeding tubes get clogged constantly. Proper maintenance and flushing is important.

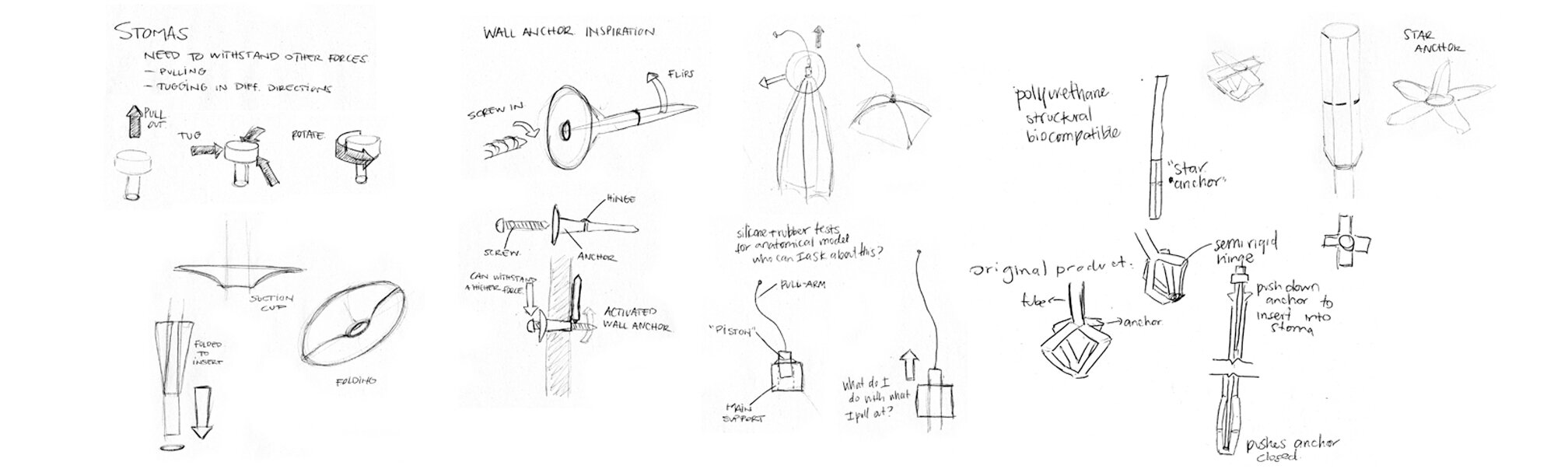

Tugging & Pulling

Physically active patients accidentally pull their tubes and buttons out, especially while sleeping.

Balloon Rupture

Retention balloon breaks and must be replaced immediately to avoid stoma closure.

Stoma Leakage

Stomach contents may leak through the stoma regardless of tube placement.

Material Decay

Stomach contents corrode silicone, so tubes must be changed every 1 to 6 months.

Develop

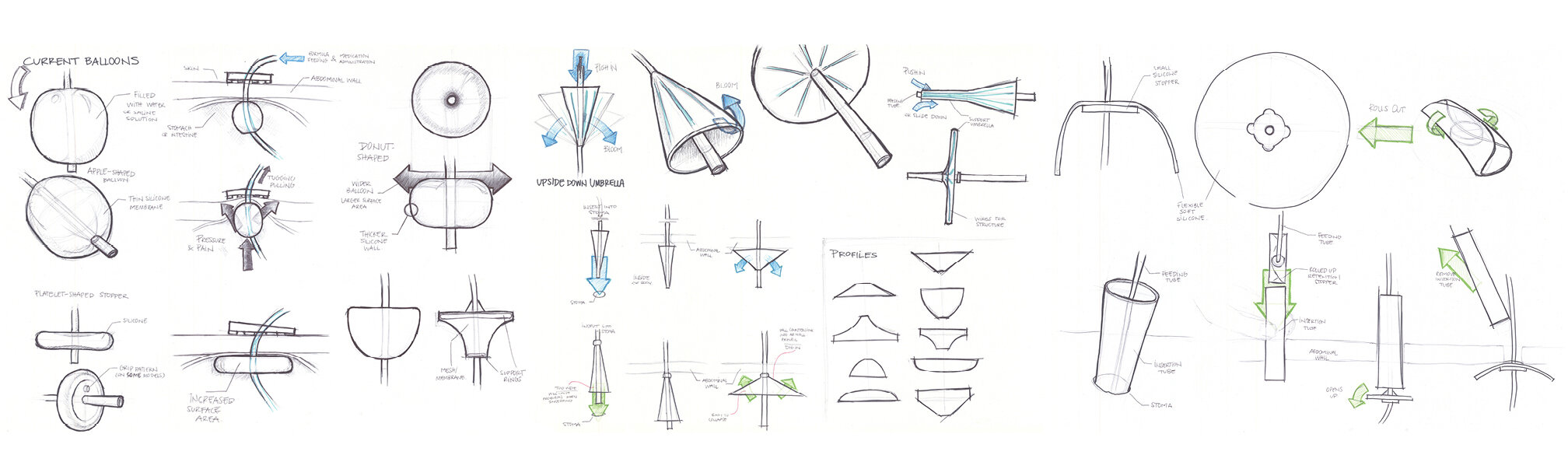

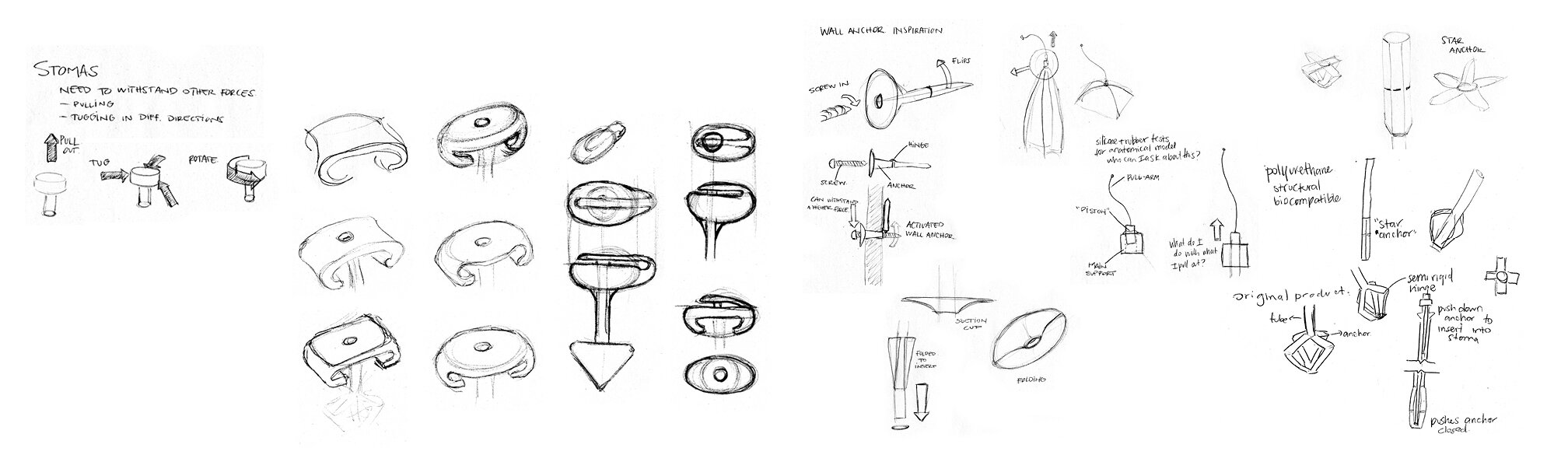

Exploring different retention mechanisms that can offer more comfort and durability.

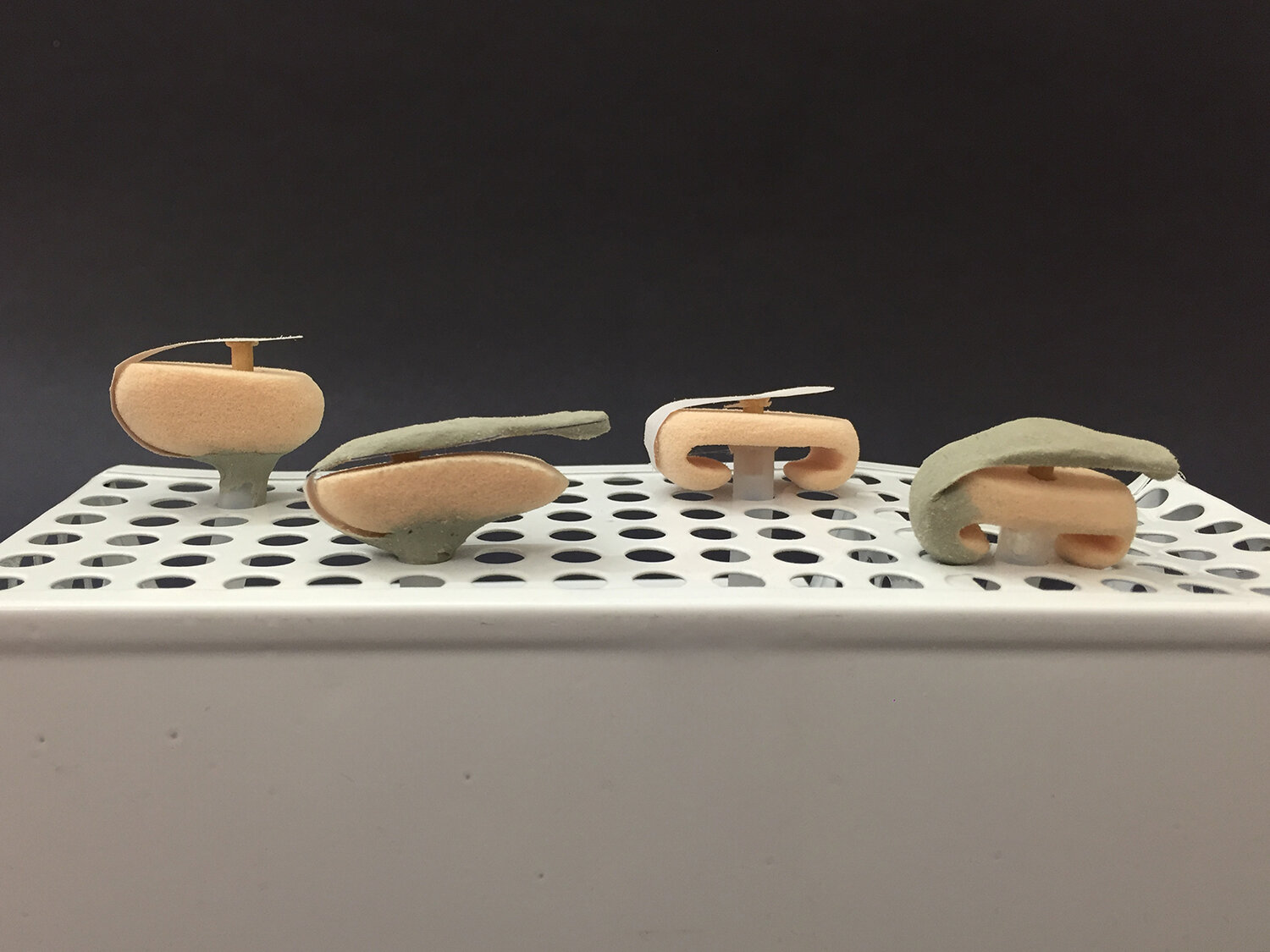

Prototype

I chose an anchor retention mechanism that has been used by Entristar as endoscopic "mushroom cage" gastrostomy tubes in patients with ALS that require enteral nutrition.

Design

Promoting calm and trust is my primary concern when designing digital and physical medical products. I implemented this by making the external side of the button feel more seamless with the body.

Conclusion

Quantity Over Quality

When prototyping and exploring ideas, creating as many as possible is a good strategy. Any idea is valid, as long as they’re being created. Through this quantity process is where we can find an appropriate solution.

Production Limitations

Sometimes there are limits to what can be recreated for a final prototype. In this case, 3D printing the button in a very flexible silicone-like material was not feasible.

Break Down to Build Up

Dividing the design into multiple parts and developing them separately allows for better refining of each one. Then the parts can come together to build a better final design.